Not many people outside our area would ever guess that on a picturesque backroad, just north of Bancroft, lies a global supplier of hydraulic seals.

The Universal Seal factory has been running since the 1960’s in our area, on the same land where it first started in a Monteagle barn years ago.

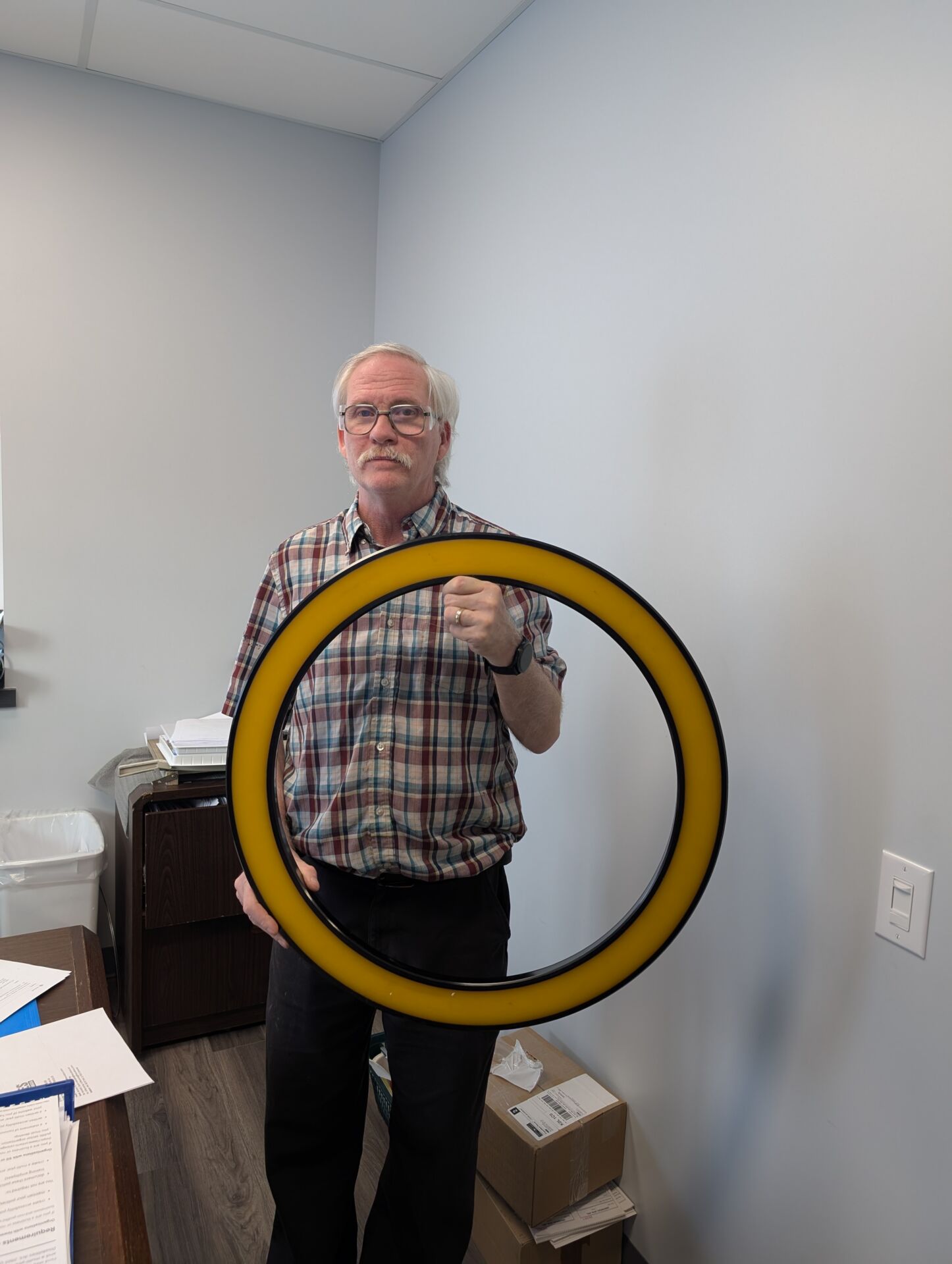

The factory makes high quality seals for things like tractors and machinery. They can make everything from the seals on a bulldozer to a giant seal used in the clutch of a ten-story- high pop-can making machine in Ohio.

General manager Blaine Shannick says that the company exports approximately 60 percent of their product to the United States.

Tarrifs will hit hard with their biggest customer being in Florida where approximately 50 percent of their products land.

“That’s going to hurt the customer because we compete in a global market, our prices are not necessarily the cheapest prices out there, but we have far beyond better quality than most of our competitors and that’s how we sell the base. But, you tack on 25%. I mean… we have to start looking at elsewhere.”

Shannick went on to note that he feels it’s not just Canada that tariffs will hurt.

“You think about the car company industries. I mean parts go back and forth across the border, 7 or 8 times, they say, to make a car. So, I mean, it doesn’t make any logical sense that we’re going through this tariff war because it’s not going to just hurt Canada. It’s going to hurt the United States. Trump may think that he’s got everything down there that he needs to run the country. But he buys a lot from everybody else, just as much as we do.”

Shannick says that his boss and her partner will be touring Europe in the spring, looking to expand their customer base.

One of the things that sets Universal Seal apart from its competitors, says Shannick, is the quality of their products. This is due to a few factors, including the company’s unique technology that uses centrifugal force. This results in all of the air being pushed out of the product and a more reliable seal.

Shannick adds that almost nothing is automated at Universal Seal. Humans are involved every step of the way, including a 100% visual inspection on all their products.

“I have a dedicated team of 5 that are checking every seal. So we don’t let anything go up that’s suspect….We are labor intensive here. Everything we do, somebody’s got a hand on it. It’s not like you can buy an injection molding machine and go away at night and it pumps out product. Not here. We have to have bodies on the floor.”

When asked if the company would ever consider leaving Canada, Shannick explained that most of the machinery was designed and built on the premise and moving the factory is not an option.

In February, after the first tariff threat was announced, Moose FM toured the Universal Seal Factory, which currently employs 28 people.

“I mean, it’s scary.” Shannick told MooseFM when contemplating the threat of tariffs. “There’s enough chaos in the world now. We don’t need more.”

Peggy Joe Wodzak, who has worked along with Blaine at Universal Seal for over 3 decades agreed.

“I’m scared for what a tariff war could mean” she told MooseFM in February.